milling machine parts and functions ppt

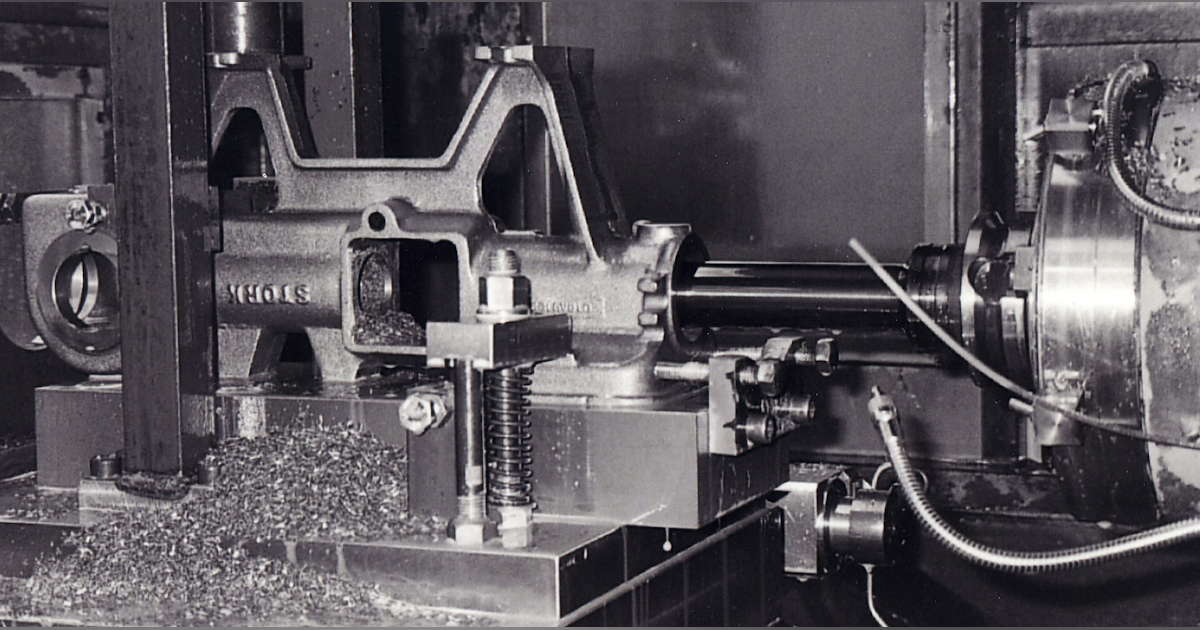

The plain horizontal milling machines column contains the drive motor and gearing and a fixed position horizontal milling machine spindle. Constant research and development activities have evolved the modern concept of machine tools.

Purchasing Procurement Process Flow Chart Process Flow Chart Process Flow Business Flow Chart

PPT On Lathe Machine 1.

. The bed can also by fed in the x y and z axes manually. The ram can be moved in or out to provide different positions for milling operations. The company has been in existence for more than a decade and has endeavored to.

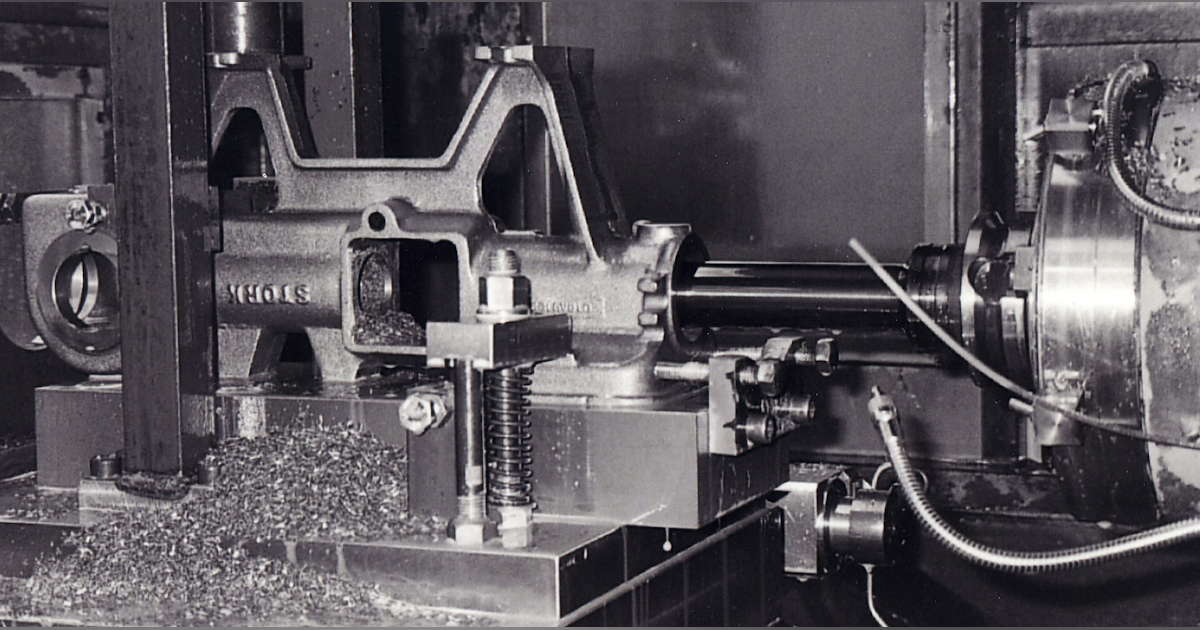

Machine Tools Drill Machine Wood Working Machinery Shearing Machine. Plain horizontal milling machine in that it is of the ram type. A tool and cutter mill uses a CNC machine tool with five axes and several grinding.

All component is mounted on the base. Precautions for Drilling machine. The milling cutter rotates at a very high speed because of the multiple cutting edges it cuts the metal at a very fast rate.

The ram-type milling machine is. Outline Introduction Construction of a lathe Principal parts a lathe Lathe operations References May 23 2017Outline CONFIDENTI4L 2014 3. The motor that rotates the milling machines spindle is the main power source that drives the machine.

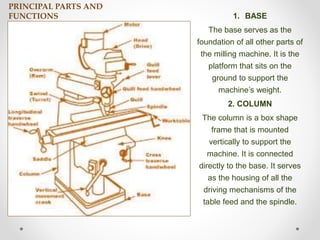

What Are the Parts of A Milling Machine. The following stated below are the milling machine parts. A milling machine removes metal by rotating a multi-toothed cutter that is fed into the moving workpiece.

A milling machine is a machine tool that cuts metal as the workpiece is fed against a rotating multipoint cutter. So let discuss all of these parts in detail. The explanation for the parts of horizontal milling machine is as follows.

Most milling machines. Milling machine parts. Lathe machine ppt 1.

This milling machine part is the foundation of a milling that carries the weight of the machine and move it to the ground. MILLING MACHINE OPERATIONS The milling machine removes metal with a revolving cutting tool called a milling cutter. It is a cover of an abrasive wheel or grinding wheel which protects the worker in any type of accidentgrinding machine parts and functions.

If you have to detach or adjust the motor you can use the handles. This base is made of cast iron due to its high compressive strength. A milling machine consists of the following parts.

This machine can also be used for cutting keyways racks and gears and for fluting taps and reamers f Types. 2 Ram-type Milling Machines. It provides support to all the parts of the machine and which can absorb the vibrations induced during milling operation and also acts as a reservoir for the cutting fluids.

Variable speed control is the milling machine part that has a function to control the speed of the motor drive by adjusting the electric power frequency that is supplied to the motor drive. The functions of the above-mentioned parts of the grinding machine are given below. This machine can also hold single or multiple cutters at the same time.

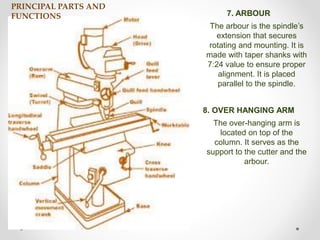

The arm and arbor supports are used to stabilize long arbors. Parts and functional importance of horizontal boring machine. Radial Milling Machine Manufacturer - Tengzhou ROOY CNC Machine Co is a machine tool manufacturing company that has gained global recognition in design and production of machine tools such as milling drilling lathe power presses and other machine tools for metal forming processes.

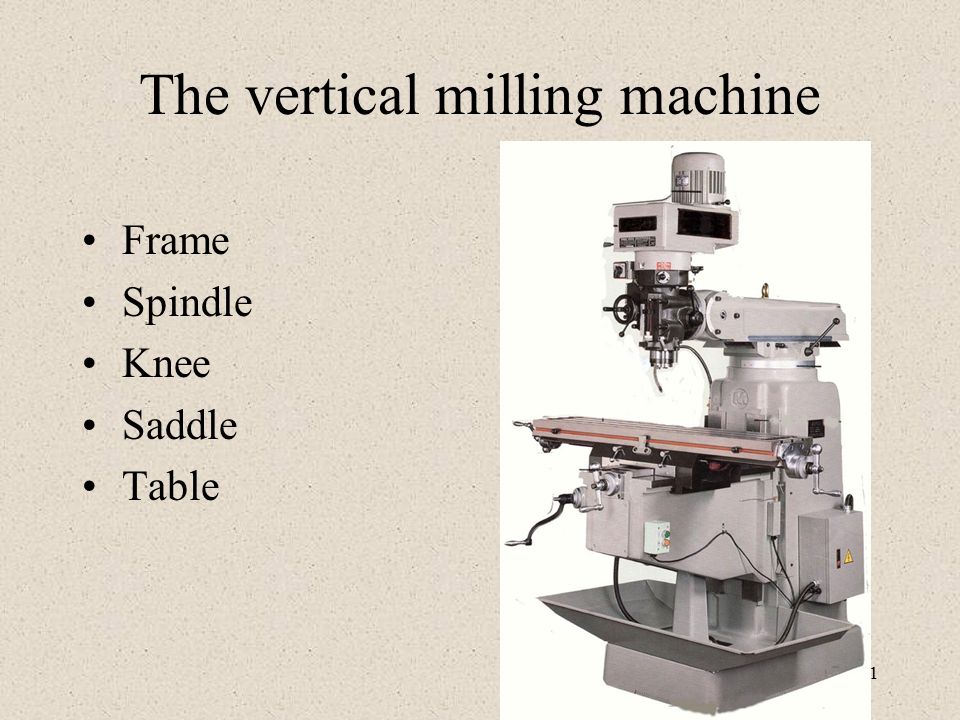

The spindle can be fed up and down with a quill feed lever on the head. Supports can be moved along the. With various attachments milling machines can be used for boring slotting circular milling dividing and drilling.

The head and the motor. The column contains an oil reservoir and a pump which lubricates the spindle. It is the foundation.

Ie the milling machine spindle is in a swivel cutter head mounted on a ram at the top of the column. CNC milling machines - CNC Milling Machines developed by ACT are inserted on desktop computer which can carry out cutting drilling and threading slotting holing removing materials from work-piece surface giving it smooth finish and great precision by mounting the milling machine over the Desktop CNC. The head part of the machine contains the motor secure and comes with adjustable handles that you can use for the motor.

The motor has a function to convert electric power becomes mechanical power so the machine can move. This study guide has been designed to directly represent the questions that will be found on the open book written assessment and as an aid for the hands-on usability assessment. Ad Browse Our Wide Selection Of Milling Machine Parts Online Request A Custom Quote Today.

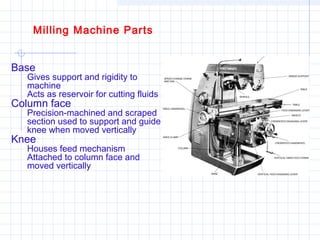

Nowadays a wide range of latest machinery is manufactured and readily available in the market. The Milling Machine consists of Base Column Knee Saddle Table Over-Arm Spindle or Arbor Arbor supports Ram and Milling Head. Objectives Main purpose of the centre lathe Safety precautions on the centre lathe Types of Lathe Identify main parts of the centre lathe State the purpose of each main parts Method of Holding work Method of cutting tapers Cutting speed on the Lathe.

Abrasive Wheel Head-. 5 Machines should be lightly oiled to prevent from rusting. An adjustable overhead arm containing one or more arbor supports projects forward from the top of the column.

The column rests on the base and base contains coolant reservoir and a pump which is used during machining operation that requires. Once an axis is located at a desired position and will no longer be fed it should be locked into position with the gibb locks. 2 Machines should be cleaned after use 3 Chips should be removed using brush.

1 Lubrication is important to remove heat and friction. Above column we have overarm. 4 T-slots grooves spindles sleeves belts pulley should be cleaned.

The main parts of the machine include base and column knee saddle and swivel table power feed mechanism table spindle overarm arbor arbor support and ram. We will study one by one in detail. A milling machine consists of the following parts.

ANAND KUMAR Roll No- ME 13 710 Topic of presentation- Lathe Machine 2. Column and base provide supports for the other parts of a milling machine. Column including base is the main casting that supports all other parts of milling machine.

Vertical Milling Machine This study guide will cover the major working parts functions and machining techniques that can be foundused on most vertical milling machines. There is an oil reservoir and pump in the column to lubricate the spindle. An explanation for the parts of horizontal milling machine.

Here in this Milling machine diagram you can easily see Its parts. A milling machine has Column and Base Knee Saddle and Swivel Table Power Feed Mechanism Table Spindle Over Arm Overhanging Arm Arbor Support and Ram.

What Is Milling Machine Operation Parts And Types Mechanical Booster

Universal Milling Machine Vertical Horizontal China Manufacturers Supplier

Parts Of Cnc Machines Mechanical Power Inc

What Is Milling Machine Operation Parts And Types Mechanical Booster

The Vertical Milling Machine Ppt Download

Combing Machine Diagram Comber Diagram Passage

Strimmer Trimmer Saw Cutter Carb Carburettor For 43 49cc Engine Machine Part Carburetor Chainsaw Trimmers

Aerodynamics Of An Airplane Wing Seminar Report And Ppt Flugtechnik Flug Technik

Cutting Tool Applications Chapter 10 Boring Operations And Machines American Machinist

Universal Milling Machine Vertical Horizontal China Manufacturers Supplier

Introduction To Milling Machines

Milling Machine Types Working Parts Operations Cutting Parameter

Machine Tool Description History Types Facts Britannica

Milling Machine Parts Types Operations Milling Cutter Pdf